Borosilicate Foam Glass Brick

Borosilicate foam glass bricks are inorganic closed-cell insulation materials made primarily from borosilicate glass, crushed and mixed with additives and foaming agents, then produced through high-temperature foaming and cooling processes. This material features superior impermeability and waterproof performance, with good acid resistance (except for hydrofluoric acid). Borosilicate foam glass bricks, adhesives, and primers together form a reliable corrosion protection system for chimney interiors, providing excellent thermal insulation, waterproofing, and corrosion resistance.

1. Application Range

Chimneys and flues after flue gas desulfurization in coal-fired power plants. The corrosion protection system is applicable to substrates such as metals, concrete, refractory bricks, and FRP; it can also be used for cryogenic equipment and pipeline insulation.

2. Product Characteristics

★Lightweight, low thermal conductivity, high compressive strength;

★Waterproof, non-hygroscopic, and leak-proof;

★Inorganic materials, non-aging, non-combustible, non-moldy, corrosion-resistant, with long service life;

★Suitable for various harsh environments such as high temperatures and deep freezes;

★Stable physical and chemical properties with dimensional stability, easy to cut;

★Very low thermal expansion coefficient, capable of withstanding a wide range of high and low temperature shocks..

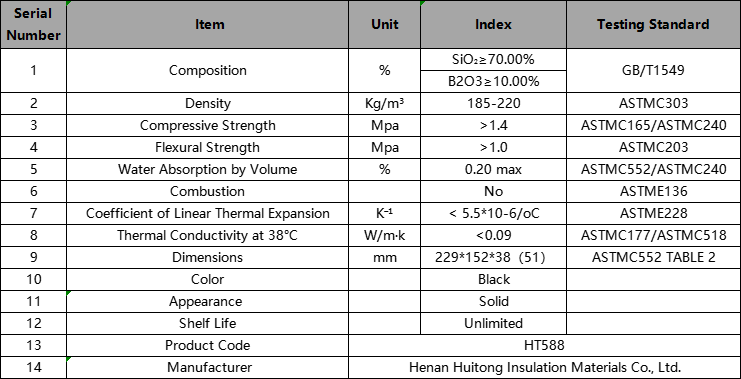

3. Physical Performance Indicators

4 . Packaging and Storage

★Products are packaged in cartons for easy transport, installation, and identification.

★ During transportation, materials must be kept clean.

★Packaging boxes must have the manufacturer's name, product specifications, product name, transportation, storage safety, precautions, etc. printed on the external wall.

★Each panel and layer should be separated by cardboard.

★Storage must be waterproof, stacked no higher than 6 layers.

5. Validity Period

Indefinite