Polurethane Adhesive

Polyurethane adhesive is an elastomeric anti-corrosion material developed specifically for the inner lining of coal-fired chimneys, sewage treatment tanks, chemical processing tanks, etc. It features good adhesion, high elasticity, and resistance to penetration, capable of withstanding strong corrosive acidic liquids at both normal and high temperatures. It is widely used for the internal anti-corrosion of coal-fired chimney interiors, sewage treatment plants, chemical plants, power plants, etc.

1. Product Characteristics

★Two-component, cures at room temperature;

★Good adhesion with substrates;

★Good elasticity, less prone to stress failure;

★Can withstand strong acid solutions for extended periods;

★Usable below 150℃ for long periods, with short-term tolerance for temperatures above 150℃;

★No harmful gas emissions, safe for humans and non-polluting to the environment.

2. Main Uses

Anti-corrosion for coal-fired chimney interiors, sewage treatment plants, chemical factories, etc.

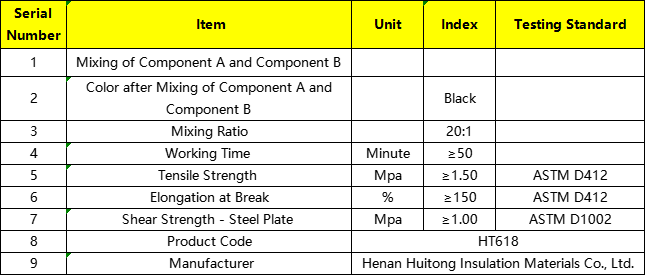

3. Product Indicators (Not to be used as product standards)

4. Color

Component A is black, Component B is light yellow, and mixed it appears black.

5. Packaging

Component A is packaged in white plastic barrels, 20kg/barrel; Component B is packaged in plastic bottles, 1.0kg/barrel.

Quality ratio: A:B = 20:1

6. Usage Conditions

★When cleaning porous substrates, grinding is required based on their characteristics.

★After grinding, a lot of dust remains on the substrate surface, which should be cleaned with a brush or broom. Then rinse with high-pressure water and allow to air dry or heat dry to avoid dust adhering to the surface again;

★The cleaned surface should not be subjected to any form of pollution before applying adhesive; if the surface is left unused for an extended period after cleaning, it must be re-cleaned before construction.

★The substrate surface must be solid, flat, clean, and dry, with no powdering, sand, hollowing, or flaking.

7. Storage and Validity Period

Stored at a cool, dry place, in unopened sealed containers, before use, with a shelf life of 12 months from production date. Please check the production date on the product packaging.

8. Precautions

★ Not suitable for frosted or damp substrate surfaces;

★ Construction is not advisable when material surface temperature is below 0℃ or above 50℃;

★ Components A and B must be thoroughly mixed to avoid unevenness that could affect the performance of the elastic material;

★ Components A and B should be stored separately and used as mixed, and to avoid waste, mix only when needed;

★ For adhesion related construction, check adhesion performance beforehand and contact relevant technical service departments if needed;

★ Direct contact with eyes and skin may cause temporary discomfort; in such situations, rinse with plenty of water and seek medical attention if necessary.