Primer

This product is a two-component paint made from modified epoxy resin, red iron oxide, anti-corrosive pigments, corrosive fillers, specialty additives, solvents, etc., designed specifically for corrosion protection. AB two-component packaging.

1. Product Performance

Can be used in conjunction with various topcoats at room temperature, with a fast-drying film and excellent physical-mechanical properties, making it convenient and simple to apply.

2. Main Uses

Can be widely used for anti-rust priming on chemical equipment, petroleum equipment, power equipment, railways, bridges, steel structure plants, tower cranes, automobiles, machine tools, etc., in harsher environments.

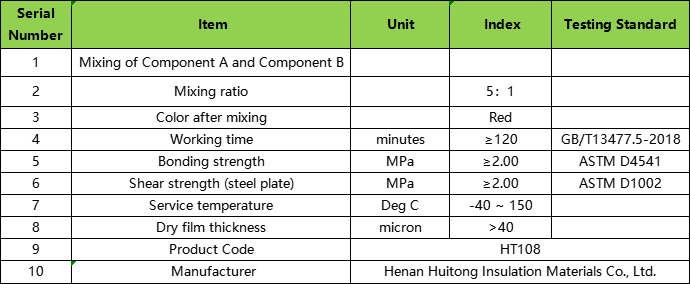

3. Product Technical Indicators

4. Construction Parameters

★Mixing method: Thoroughly stir the paint before use until no sediment remains at the bottom. Mix in a ratio of paint to curing agent = 5:1 (or according to the ratio specified on the packaging) for construction.

★ Suggested usage period: Mix only what you need, use the mixed paint within 4 hours.

★ Surface treatment requirements: Surfaces must be rust-free, oil-free, dust-free, and water-free to reach grade sa2.5. The cement substrate surfaces must be free of dust, debris, and looseness to increase the adhesion and durability of the paint film.

★ The film thickness: The dry film thickness for a single application should be greater than approximately 50μm.

★ Theoretical usage amount: Without considering the actual construction environment, method, surface condition, structure, and shape, the general consumption is 0.50kg/m².

5. Packaging and Storage:

★Package: Sealed in iron drums, with each drum containing 18kg of paint and 3.6kg of curing agent.

★Store and transport away from fire sources in a well-ventilated, cool, dry place, avoiding sunlight and rain.

★Valid period: One year, if it exceeds the validity period, it can still be used after re-checking for compliance.