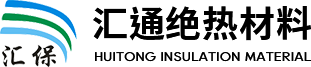

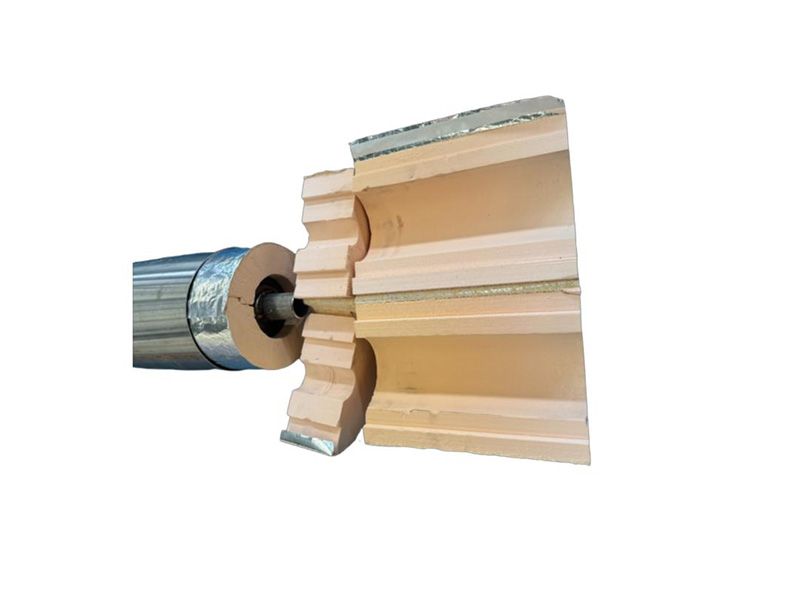

Foam Glass Plates / Pipe Shells

Foam glass is an inorganic thermal insulation material with a large number of uniform, independent and closed pore structures. It is mainly made from formulated glass particles melted in a melting furnace, mixed with an appropriate amount of foaming agents and other additives, heated and melted in a natural gas roller kiln and then cooled in an annealing furnace. It completely retains the chemical stability of inorganic glass. It features low bulk density, low thermal conductivity, being impermeable to moisture, non-absorbent, non-combustible, non-mildewable, resistant to rodents, having high mechanical strength and being easy to process. It can withstand all chemical corrosion except that of hydrogen fluoride and is known as a green and environmentally friendly thermal insulation material. The annual output of foam glass is 40,000 cubic meters.

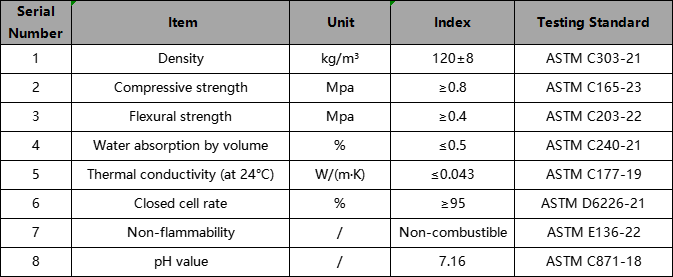

1.Product Standard: ASTM C552 - 2021

2.Main Technical Indicators

3.Packaging and Storage

Ø Packed in carton boxes;

Ø When loading onto vehicles, stack them tightly to prevent tilting;

Ø Store in a dry and ventilated environment and avoid getting wet by rain;

Ø The stacking height should not exceed five layers.

4.Precautions

Ø Foam glass is fragile. Handle it with care during transportation and handling;

Ø When insulating equipment or pipelines, use auxiliary materials such as mastic, sealant and fiberglass mesh cloth for sealing, moisture-proofing and fixing;

Ø It can be cut with tools during the installation process.