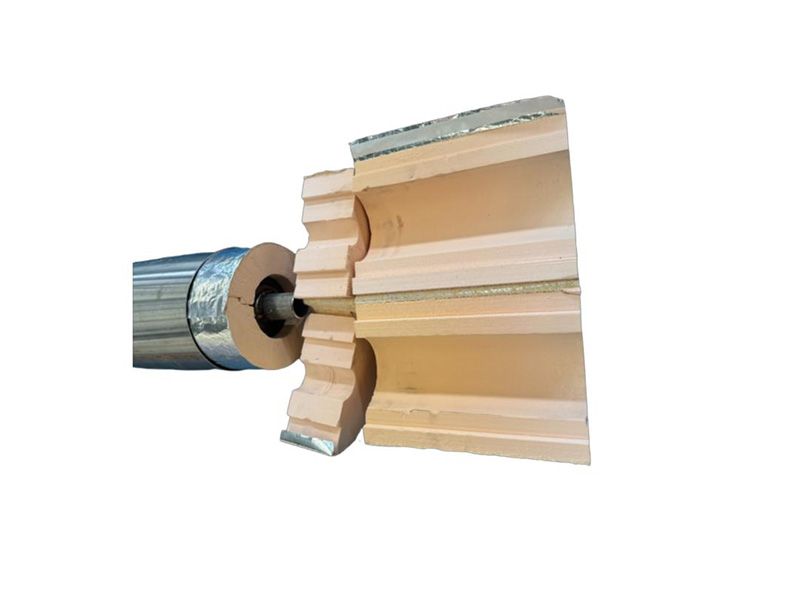

Polyisocyanurate Foam (PIR)

PIR is a foam material made from the reaction between isocyanate and polyether under catalysis. Its physical and fire-resistant properties are superior to those of regular polyurethane. It is an ideal organic low-temperature thermal insulation material with a low thermal conductivity, lightweight, shock-absorbing, and adaptable. It is widely used in refineries, chemical plants, ethylene production, fertilizer plants, cold storage, and the construction industry for insulation and thermal protection.

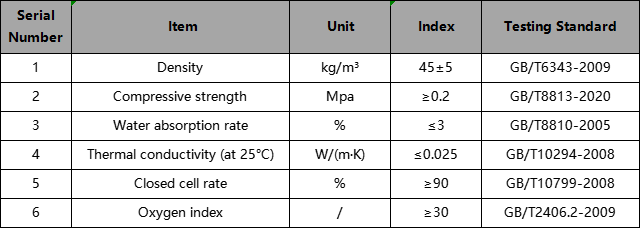

1. Product Standards:GB/T 25997-2020

2. Main Technical Indicators

3. Packaging and Storage

Ø Bundled packaging;

Ø When loading, ensure the products are packed tightly to avoid impact;

Ø Store in a waterproof, moisture-proof, light-proof, dry, and well-ventilated area;

Ø Keep away from heat sources, and avoid direct sunlight.

4. Notes

Ø Handle with care during transportation and handling;

Ø When insulating equipment or pipelines, use additional materials such as mastics, sealants, and mesh cloth for sealing, moisture-proofing, and fixing;

Ø During installation, tools can be used for cutting.