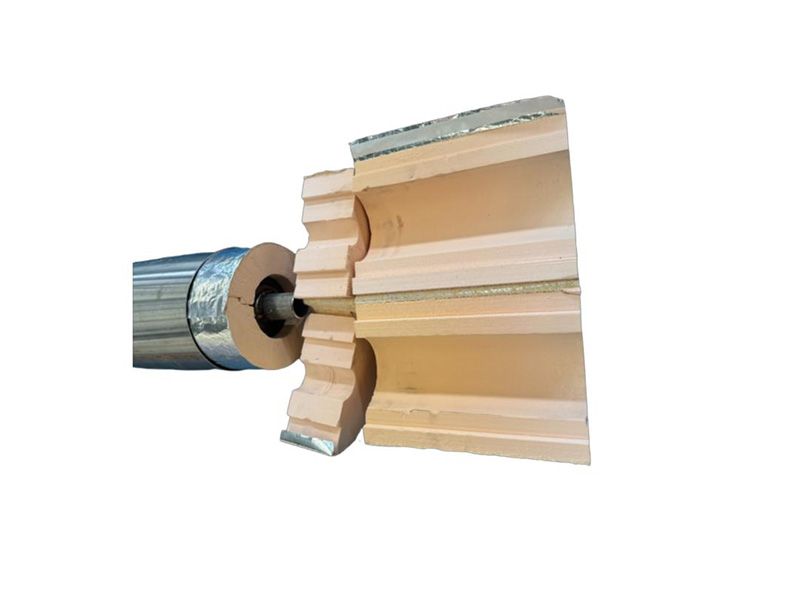

Flame Retardant Mastic

Mastic is made from rubber, asphalt, rubber, minerals, and other fillers, with the addition of appropriate flame retardants. It has excellent airtightness, waterproofing, anti-freezing, anti-corrosion properties, resistance to aging and cracking, and can be applied at low temperatures. Once dry, it exhibits flame retardant properties.

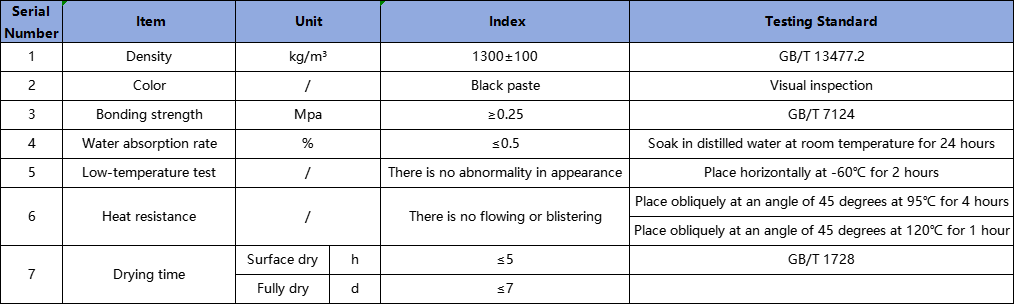

1. Product Standard: GB 50264-2013

2. Main Technical Specifications

3. Packaging and Storage

Ø Packaged in barrels, 25kg/barrel;

Ø Store in a dark, room-temperature environment.

4. Precautions

Ø Handle with care during transportation to avoid packaging damage;

Ø Store in a cool place, avoid direct sunlight;

Ø Ensure proper ventilation at the construction site;

Ø Reseal any remaining mastic for storage after use.

5. Recommended Usage: 6~8kg/㎡;